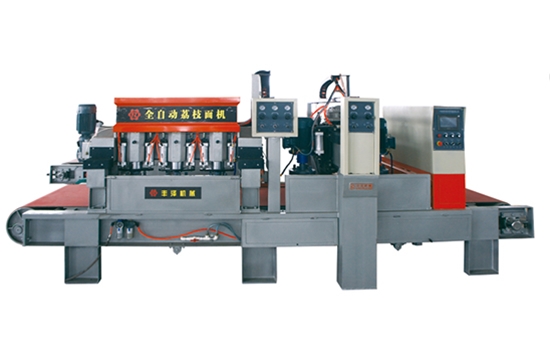

2. it can improve the grinding speed, reduce the cost and improve the efficiency. It can process 60-80 square meters of litchi panel materials per hour.

3. the cross operation of two beams can avoid repeated grinding of multiple heads. It can make the board surface more uniform, plain and beautiful.

4. for the processing of lychee antique surface, the No. 3, No. 4 and No. 5 grinding heads can be replaced with polishing brushes. In this way, the No. 1 and No. 2 grinding heads can be polished successfully, and the No. 3, No. 4 and No. 5 grinding heads can be polished once, which can more effectively reduce costs and obtain greater benefits.

5. the first two grinding heads are polished with motor load, which is not easy to rebound, and is more conducive to the breaking of the plate surface. The last three grinding heads are of slide type, which has light load, reduces the plate pressure, reduces the damage rate, improves the efficiency, and is more suitable for the processing of hard and poor toughness plates.

|

total power |

24KW |

|

power |

380V 50HZ |

|

maximum machining width |

1000mm |

|

maximum machining thickness |

100mm |

|

main engine dimensions |

5200×1800×1600mm |

|

auxiliary transition frame |

2500×1100×680mm |

|

weight |

3500KG |